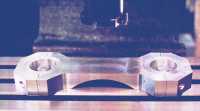

Boring

the holes for the fork slider tubes.

Boring

the holes for the fork slider tubes.

Boring

the holes for the fork slider tubes.

Boring

the holes for the fork slider tubes.

Setting

up the brace for milling the fender curve. Here's a larger

view, and a view from the back showing the

required clamping.

Setting

up the brace for milling the fender curve. Here's a larger

view, and a view from the back showing the

required clamping.

Cutting

the fender curve on the rotary table. Yep, that's a face mill, not

an end mill. It's the only cutter I had at the time that was long

enough. Now I have a shell end mill, much quicker.

Cutting

the fender curve on the rotary table. Yep, that's a face mill, not

an end mill. It's the only cutter I had at the time that was long

enough. Now I have a shell end mill, much quicker.

Here's another view.

Facing

the brace. Note the clamping plugs in the holes - they get milled

at the same time.

Facing

the brace. Note the clamping plugs in the holes - they get milled

at the same time.

The

finished brace, including the collars for the dust caps.

The

finished brace, including the collars for the dust caps.